surface grinding machine pdf

Metrology and Properties An international forum for academics industrialists and engineers to publish the latest research in surface topography measurement and characterisation instrumentation development and the properties of surfaces. A cutting speed for mild steel of 100 ftmin is the same whether it is the speed of the cutter passing over the workpiece such as in a turning operation or the speed of the cutter moving past a workpiece such as in a milling operation.

Surface Grinder Surface Grinding Machine Cnc Surface Grinding Machine Mumbai India

The concept of broaching can be traced back to the early 1850s with the first applications used for cutting keyways in pulleys and gearsAfter World War I broaching was used to rifle gun barrelsIn the 1920s and 30s the tolerances were tightened and the cost reduced thanks to advances in form grinding and broaching machines.

. Oct 11 2022 The Expresswire -- Floor Grinding Machine Market Insights 2022 at 280 Million USD in 2018 and is projected to reach 330 Million USD by 2025. Road surface marking is any kind of device or material that is used on a road surface in order to convey official information. The cylindrical surface is grinded with a machine in which grinding wheel is fitted on the shaft of a free electric motor.

There are various kinds of cutting fluids which include oils oil-water emulsions pastes gels aerosols mists and air or other gasesCutting fluids are made from petroleum distillates animal fats plant oils water and air or other raw ingredients. Definition Diagram Parts Working Advantages Disadvantages and Applications PDF Drilling Machine is used to make circular holes on the components with the help of Drill bits. Microsofts Activision Blizzard deal is key to the companys mobile gaming efforts.

Those who have a checking or savings account but also use financial alternatives like check cashing services are considered underbanked. A surface grinder is a machine tool used to provide precision ground surfaces either to a critical size or for the surface finish. There are several types of hones but all include one or more abrasive stones that are under pressure against the surface they are working onSpecial honing attachments are fixed for honing.

These are of the following three kinds. Other grinding types such as creep feed grinding are also performed. Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment leaving a clean surface with a significant specular reflection still limited by the index of refraction of the material according to the Fresnel equations.

It is the most important machine in the tool room as nearly all the operations can be performed on it with high accuracy. ASCII characters only characters found on a standard US keyboard. Honing stone is made of aluminum oxide silicon carbide or diamond dust which are selected according to the.

Microsoft is quietly building a mobile Xbox store that will rely on Activision and King games. The process depends on the. In this type of grinders the grinding wheel is fitted on the machines work table which can be given crossfeed and the entire surface of the job can be grinded.

It replaces tools like the mincing knife which are also used in the preparation of minced meat filling etc. This type has the same kinematics of surface grinding but also has a unique distinction as it removes a high amount of material from the workpiece. To help achieve the high removal rate the workpiece speed should be low with a high-power grinding machine 3.

A flexible electrical drilling machine and a honing stone are used. Its cut is analogous to that of a lathe except that it is archetypally linear instead of helical. Cutting speed may be defined as the rate at the workpiece surface irrespective of the machining operation used.

Must contain at least 4 different symbols. The food to be minced is placed into a funnel which sits on top of the grinder. In some materials such as metals glasses black or transparent stones polishing is also able to reduce diffuse.

A meat grinder also called a meat mincer in the UK is a kitchen appliance for fine chopping mincing andor mixing of raw or cooked meat fish vegetables or similar food. A grinding machine often shortened to grinder is a power tool or machine tool used for grindingIt is a type of machining using an abrasive wheel as the cutting toolEach grain of abrasive on the wheels surface cuts a small chip from the workpiece via shear deformation. They are commonly placed with road marking machines also referred to as road marking equipment or pavement marking equipmentThey can also be applied in other facilities used by vehicles to mark parking spaces or designate areas for other uses.

An abrasive is a material often a mineral that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by frictionWhile finishing a material often means polishing it to gain a smooth reflective surface the process can also involve roughening as in satin matte or beaded finishes. The underbanked represented 14 of US. Whereas in Todays article we.

A wood shaper is a functionally different woodworking tool typically with a powered rotating cutting head and manually fed workpiece. A machine shop or engineering workshop UK is a room building or company where machining a form of subtractive manufacturing is doneIn a machine shop machinists use machine tools and cutting tools to make parts usually of metal or plastic but sometimes of other materials such as glass or woodA machine shop can be a small business such as a job. Both internal and external surface of a workpiece may be ground by using a.

The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutterThe metal removal rate is higher very high as the cutter has a high speed and many cutting edges. That means the impact could spread far beyond the agencys payday lending rule. In short the ceramics which are used to cut.

A shaper is a type of machine tool that uses linear relative motion between the workpiece and a single-point cutting tool to machine a linear toolpath. Grinding is used to finish workpieces that must show high surface quality eg low surface. Diamond grinding is a pavement preservation technique that corrects a variety of surface imperfections on both concrete and asphalt concrete pavements.

Numerical control also computer numerical control and commonly called CNC is the automated control of machining tools such as drills lathes mills grinders routers and 3D printers by means of a computerA CNC machine processes a piece of material metal plastic wood ceramic or composite to meet specifications by following coded programmed. In the last article we had discussed the Drilling Machine Surface Grinding Machine Milling Machine lathe machine etc. Cutting fluid is a type of coolant and lubricant designed specifically for metalworking processes such as machining and stamping.

The holding will call into question many other regulations that protect consumers with respect to credit cards bank accounts mortgage loans debt collection credit reports and identity theft tweeted Chris Peterson a former enforcement attorney at the CFPB who is now a law. The typical precision of a surface grinder depends on the type and usage however 0002 mm 00001 in should be achievable on most surface grinders. Grinding is the operation of removing the metal in the form of minute chips by feeding the work against a rotating abrasive wheel known as the grinding wheel.

6 to 30 characters long. Most often utilized on concrete pavement diamond grinding is typically performed in conjunction with other concrete pavement preservation CPP techniques such as road slab stabilization full- and partial-depth repair.

Chapter 5 Surface Grinder Manufacturing Processes 4 5

Kgsm1224 High Precision Surface Grinding Machine Table Size 600 300 Surface Grinder Grinding Machine Aliexpress

Tos Bph 20 10 X 25 Surface Grinder Operator S Parts Manual Ozark Tool Manuals Books

Kent Usa Kgs 618 Kent Industrial Pdf Catalogs Technical Documentation Brochure

Pneumatic Surface Grinding Machine

Hydraulic Circuit For Milling Machine Explained In Details Engineering Arena

Rotary Table Grinders Gockel America

6 X 12 Surface Grinder With Stand At Grizzly Com

Clausing Surface Grinders 600 Group Pdf Catalogs Technical Documentation Brochure

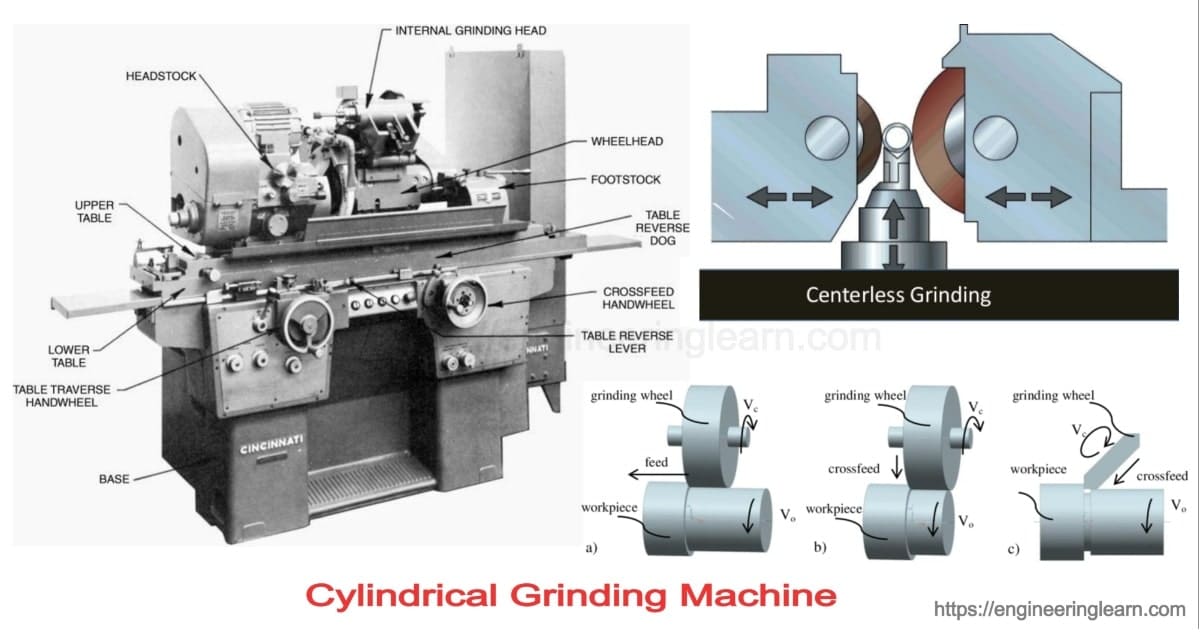

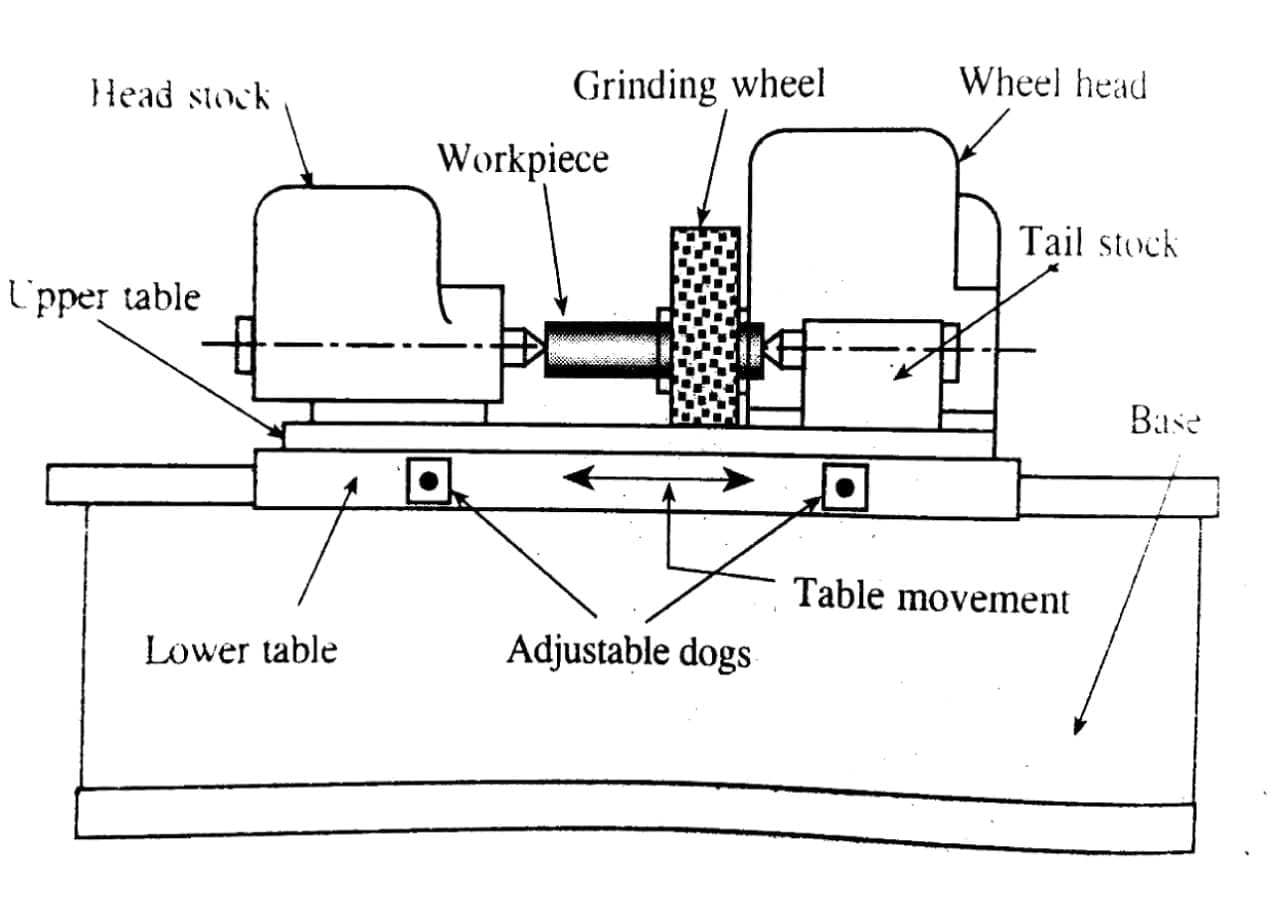

Cylindrical Grinding Machine Working Parts Types Uses

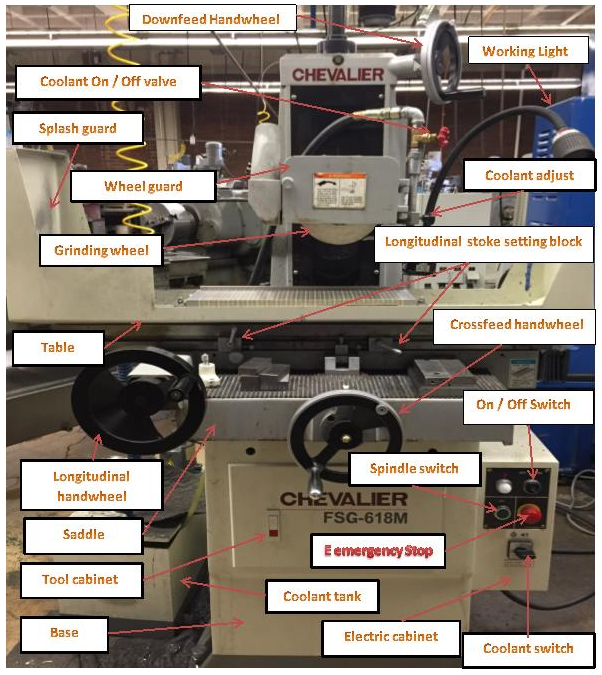

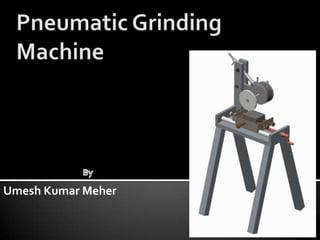

Identifying Machine Parts And Their Functions Cad Cam Engineering Worldwide

14 Types Of Grinding Machines Working Diagram Pdf

Cylindrical Grinding Machine Types Process Working Principle Engineering Learn

Surface Grinding Part 1 Basic Principals Wheel Dressing Prepping For First Cut Speeds Feeds Youtube

8 Types Of Grinding Machine Parts Working Principle Grinding Wheel Complete Details Engineering Learn

High Performance Surface Grinding Machines Fsg1224adiv 1632adiv 1640adiv Maschinen Wagner Werkzeugmaschinen Gmbh Pdf Catalogs Technical Documentation Brochure

Grinding Machine Definition Parts Working Principle Operation Advantages Application Notes Pdf

Hfs F Advance Series Conventional Surface Grinders Knuth

High Quality Auto Ahr 50150 Moving Column Precision Surface Grinding Machine Suface Grinder Buy Auto Surface Grinding Machine Precision Surface Grinding Machine Moving Column Precision Grinding Machine Product On Alibaba Com